Modern, efficient and economical

WASTE WOOD PROCESSING – Modern, Efficient, and Cost-Effective

WASTE WOOD PROCESSING

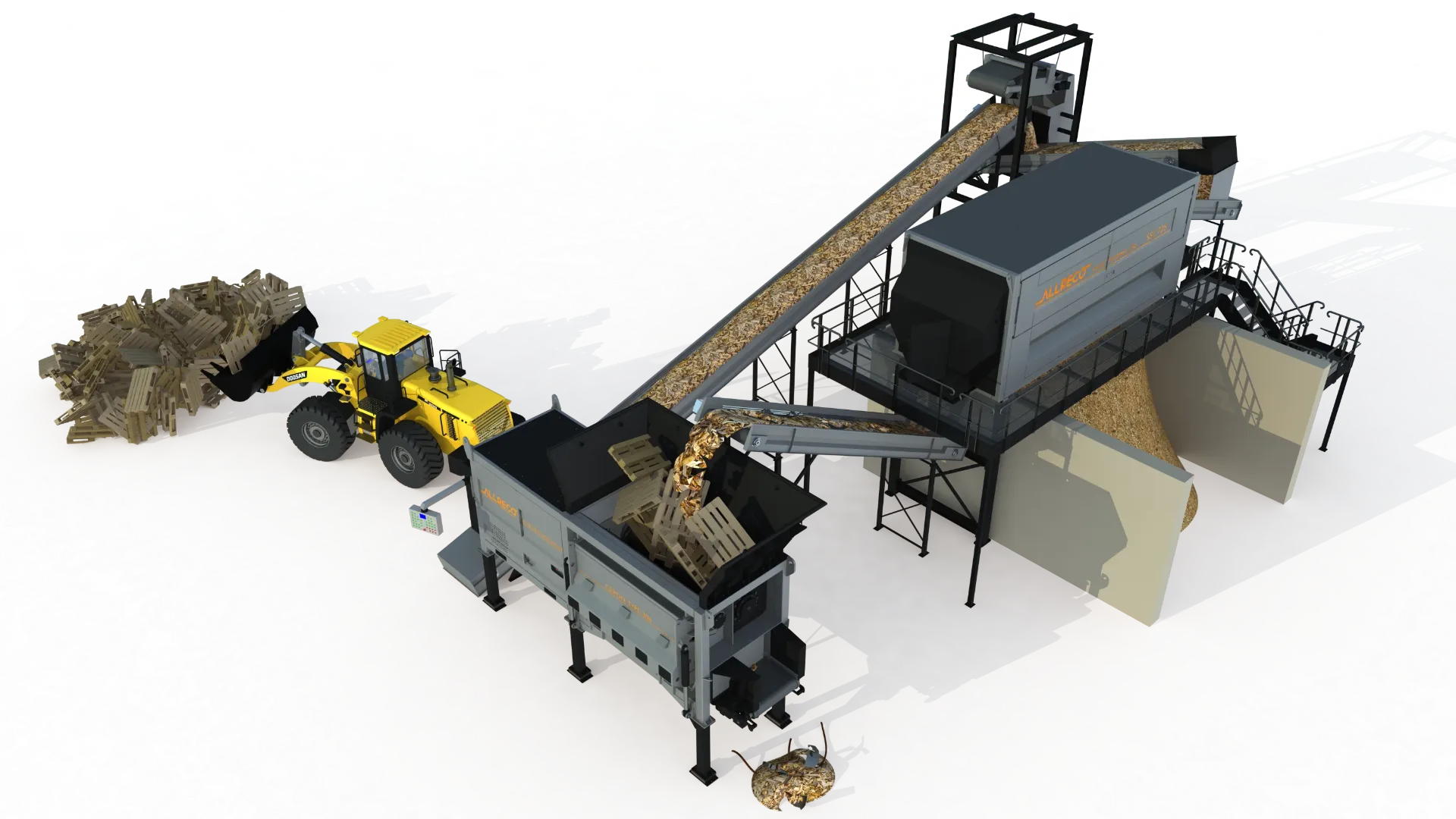

The waste wood processing system combines robust technology with intelligent process design to deliver maximum efficiency and top-quality output. With an optimized blend of shredding and screening units, cutting-edge technology, and innovative sensor systems, we provide solutions tailored precisely to your processing needs.

- Application

- Specials

- Downloads and Datasheets

Applications

Waste Wood

Specials

Tailored depth of processing

Modern slow-speed shredders minimize fines, reduce production costs, and deliver high-quality output. You define the processing depth—we deliver the optimal concept.

Smart process with oversize grain recirculation

Our design eliminates the need for a second shredding stage by using a generously sized pre-shredder. Oversize material is intelligently recirculated, lowering energy use, reducing wear, and cutting costs.

Increased uptime with impurity-resistant shredders

The system’s shredders are built to handle impurities with ease, minimizing downtime and eliminating unnecessary work stoppages.

Efficient with or without secondary shredding

For finer output requirements (e.g., <80 mm), our proven AK series shredders can be seamlessly integrated or operated as stand-alone units—delivering flexibility without compromising performance.

This is a modular, scalable, and economical system that ensures efficient waste wood processing—adapted to your operation, your goals, and your materials.