AIRFLEX 1500

With a completely redesigned, modern design, the AirFlex 1500 draws on the old virtues of the WS 1600 AB – and masters even the most difficult separation tasks. Its advantage lies in the high flexibility and sophisticated options that combine to form a powerful process unit at the highest technological level.

Applications:

Landfill dismantling, compost processing, industrial waste, alternative fuels, mixed construction waste, compost sieve overflow.

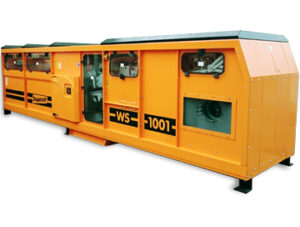

WS 1001

Compact and extremely powerful, the WS 1001 wind sifter delivers high throughput. It separates the material into up to three fractions with fast belt speed and aerodynamic efficiency.

Applications:

Landfill dismantling, compost processing, industrial waste, alternative fuels, mixed construction waste, compost sieve overflow.

WS 1501

Clean, fast, reliable – that’s how separation works with the WS 1501. Its 1.5 m working width and a variable relaxation space in three lengths make it a flexible separation solution for a wide variety of feed materials.

Applications:

Landfill dismantling, compost processing, industrial waste, alternative fuels, mixed construction waste, compost sieve overflow.

WS 2001

Greatest care with the highest throughput – this is what the WS 2001 wind sifter scores. It can handle up to 300 m³ of material per hour without this high throughput being at the expense of the absolutely efficient separation into up to three fractions.

Applications:

Landfill dismantling, compost processing, industrial waste, alternative fuels, mixed construction waste, compost sieve overflow.

WS 2501

More capacity pays off – in the case of the WS 2501 with an exceptionally high material throughput. With an outer width of 3 m and a large interior, this wind sifter has plenty of potential for every task, no matter how demanding.

Applications:

Compatible with all Doppstadt screening systems, it demonstrates its wide variety of possible uses and separates cleanly and quickly – from building rubble and slag to organic waste and compost.

WS 3001

As the largest and most powerful member of the WS family, the WS 3001 has an impressive hourly throughput of up to 400 m³. With a working width of 3 m, its infeed belt holds everything that should be cut extremely quickly, cleanly and reliably.

Applications:

Landfill dismantling, compost processing, industrial waste, alternative fuels, mixed construction waste, compost sieve overflow.