Solutions for all fields of application in the waste wood segment

The efficient and economical processing of waste wood requires the units to be adapted to a wide variety of challenges. High quality and throughput at low operating costs are required to fully exploit the potential of wood as a resource.

Waste wood is mainly used both energetically (combustion in biomass power plants) and materially (wood-based panel industry). Furthermore, other uses such as composting or as a mulch base are also possible.

Waste wood is a valuable resource, the processing of which is becoming increasingly important.

Examples of waste wood:

- Plywood from a separate collection

- Industrial wood waste

- Waste from wood processing such as furniture industry, floor / panel manufacture

- Wooden packaging such as pallets, boxes, cable drums

- Construction and demolition wood such as solid wood, chipboard, formwork wood

- Doors, windows, construction timber, railway sleepers

- Depending on the quality level, waste wood is used energetically (combustion in biomass power plants) or materially (wood-based panel industry).

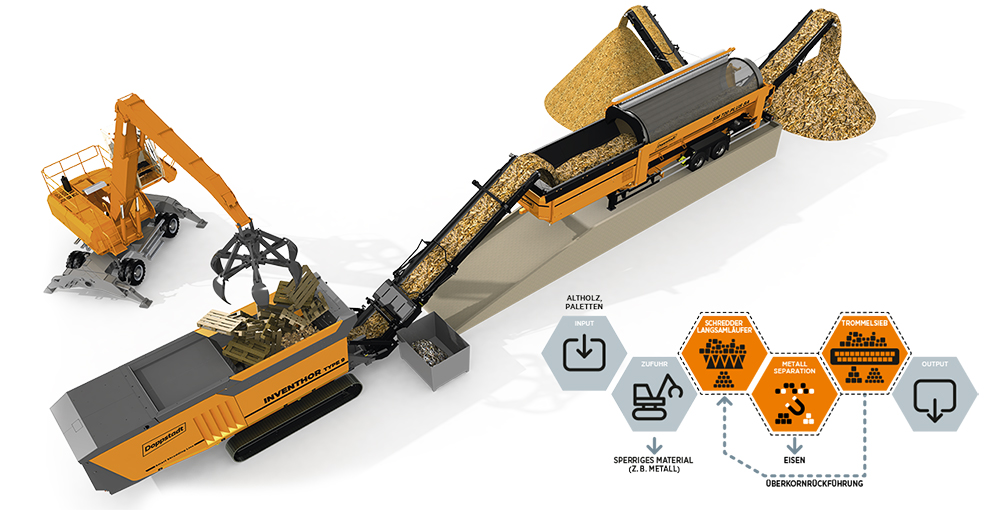

The process at a glance

Mobile

Stationary

Advantages

- Mobile modular and stationary applications for every requirement;

- Technical innovation and reliable function;

- High output quality;

- Lowest cost per ton.

Uni recycling