Hazardous & Non-hazardous waste management – Compost Screen Oversize

Process overview

Process diagram

Process description

Screening: An SM 518 is perfect for screening the finished compost and getting the most out of the subsequent treatment steps.

Wind sifting: The foils are separated from the heavy fraction and discharged into a container or onto a conveyor belt. The heavy fraction is passed over to the HDS-M via the side conveyor to undergo sink–float separation.

Sink-float separation: The HDS-M separates the stones from the wood by density. Additionally, the wood fraction is cleaned of surface contaminants such as sand in a washing drum.

Water treatment: Water treatment guarantees continuous operation and consistent separation. Depending on the material, a dosing station may also be necessary along with the lamella separator.

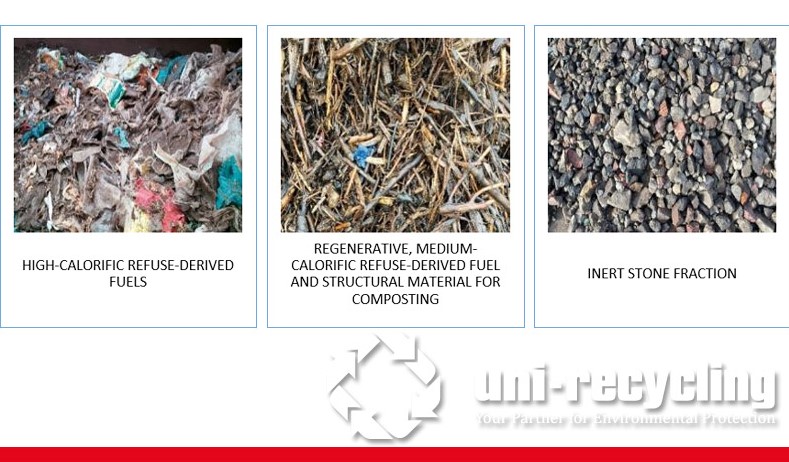

The following useful fractions are produced

Advantages

- Reduced disposal costs

- Recycling of compost structure material

- Sale of clean biomass fuel