Hazardous & Non-hazardous waste management – Source separated organics waste

Process description for separating biowaste into solids and liquids

Source separated organics (SSO) is separately collected biowaste from private households, kitchen and catering waste, overlaid foodstuff, and shop returns. This can be separated into a solid and a liquid phase using the Doppstadt screw press (DSP).

In the liquid phase, the bioavailable components are enriched and can be fed to a wet fermenter. The solid phase of the waste consists mainly of packaging material and other solids. Organic residues within the solid fraction are converted in the course of composting or biological drying respectively. After a subsequent screening, the packaging residues can be burned. The fine fraction is clean compost.

The Doppstadt mixer can mix the solid digestate fraction with green waste before it goes into the windrow. This ensures a more intensive composting and better rotting degree.

The Doppstadt screw press can be used both as a pre-treatment step for SSO and food stuff prior to a wet fermenter as well as a post-treatment step for digestate after the dry fermentation of mixed green waste and SSO. Equipped with the feeding hopper, the machine homogenizes and opens up bags and containers prior to separation into a solid and a liquid fraction.

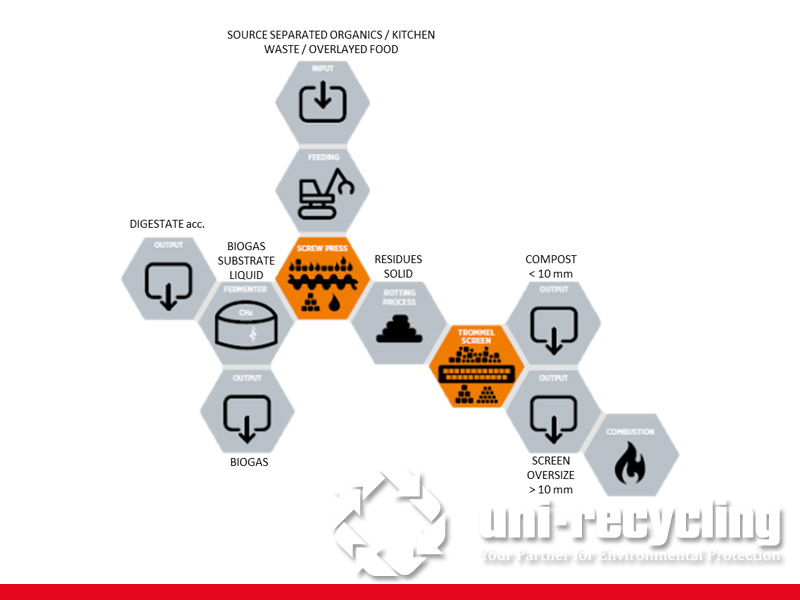

The fractions in case of a SSO pre-treatment with the DSP prior to wet fermentation are:

Treatment of SSO prior to wet fermentation – Process overview

Process description

SCREW PRESS: The screw press serves the purpose of a solid-liquid separation. In the liquid phase, the bioavailable portion for biogas production is enriched. Packaging material such as plastic, wood, or metal collects in the solid fraction.

SCREENING: The screening of the biologically dried packaging waste separates the decomposed organic residues (fines) from the plastics, glass, metal, cutlery, and other nonbiodegradable substances.

Process diagram

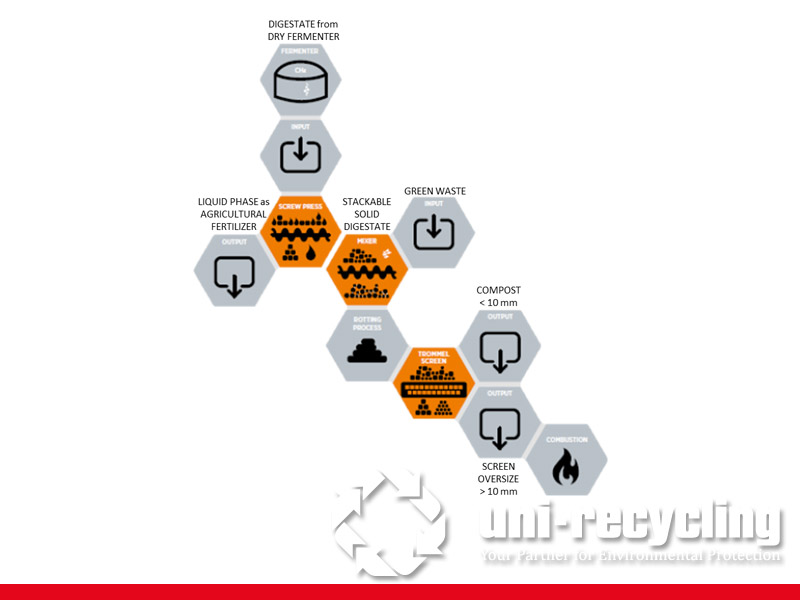

DIGESTATE AFTER DRY FERMENTER – Process overview

Process description

SCREW PRESS: The solid-liquid separation of the digestate from dry fermenters (tunnel or box) ensures that it can be stored in a more space-saving manner and is better aerated in a subsequent rotting process, reducing the duration due to less water to be evaporated.

MIXER: Solid fraction of digestate can be mixed with shredded green waste and, if necessary, other additives prior to composting to optimize aeration and pH value.

SCREENING: The compost is screened after rotting. The result is fine finished compost and coarse screen oversize which can then be returned to the composting process as structure material or, depending on its quality, used as biomass fuel in an accordingly specialized power plant.

Process diagram

Advantages

- Elimination of plastic contamination already in the biogas substrate

- Robust solid-liquid separation, tolerant to impurities up to 80 mm in diameter

- No subsequent digestate screening required

- Ideal final composting by adjusting the pH value and structure content