INVENTHOR TYPE 9

A new concept for the smart shredder generation!

UNI-RECYCLING brining a new machine to the market!

NOW available in Romania: A machine destined to set a new quality standard in the area of grinding technology!

The INVENTHOR Type 9, Doppstadt latest machine generation is based on the tried and trusted single drum principle used in the successful DW series and features a number of technological innovations.

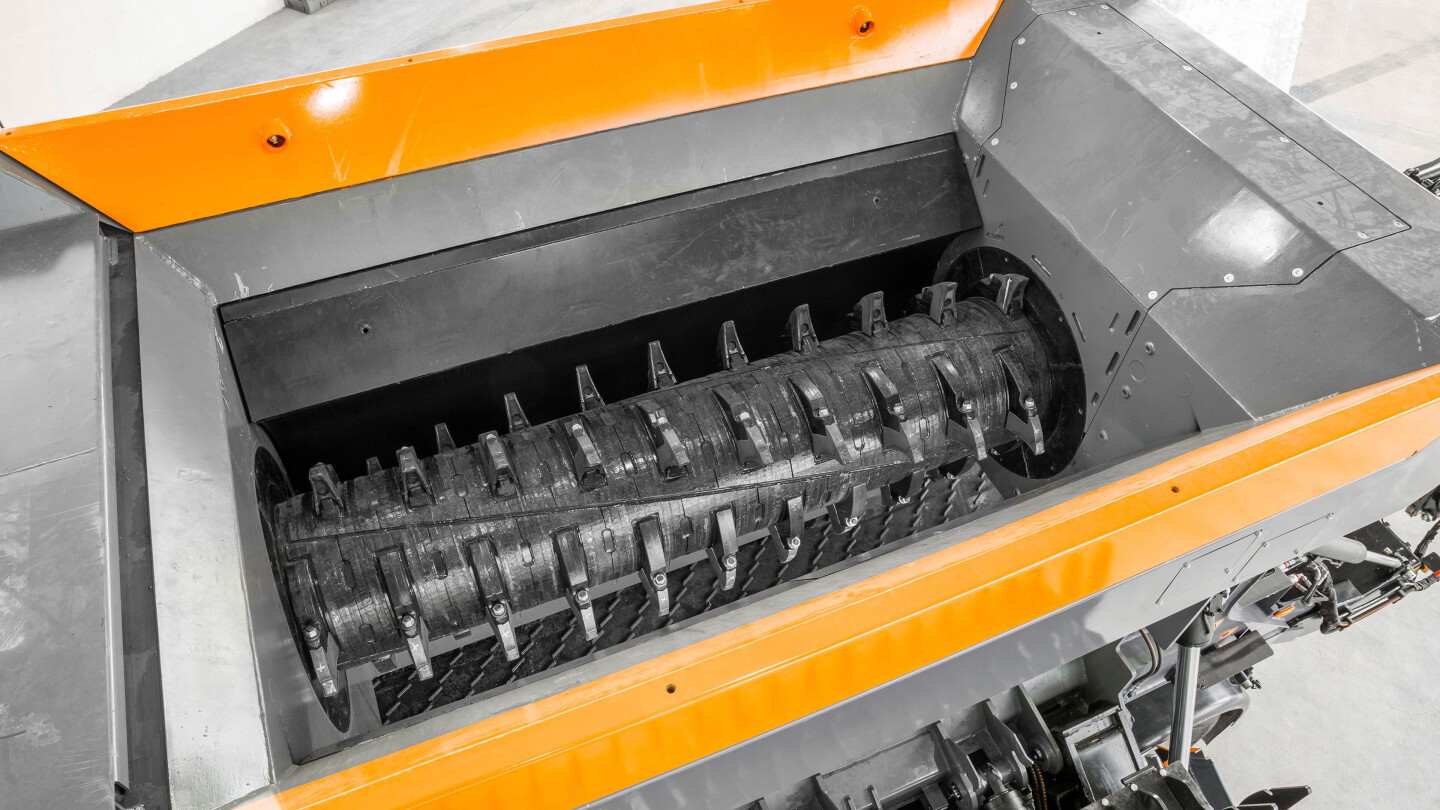

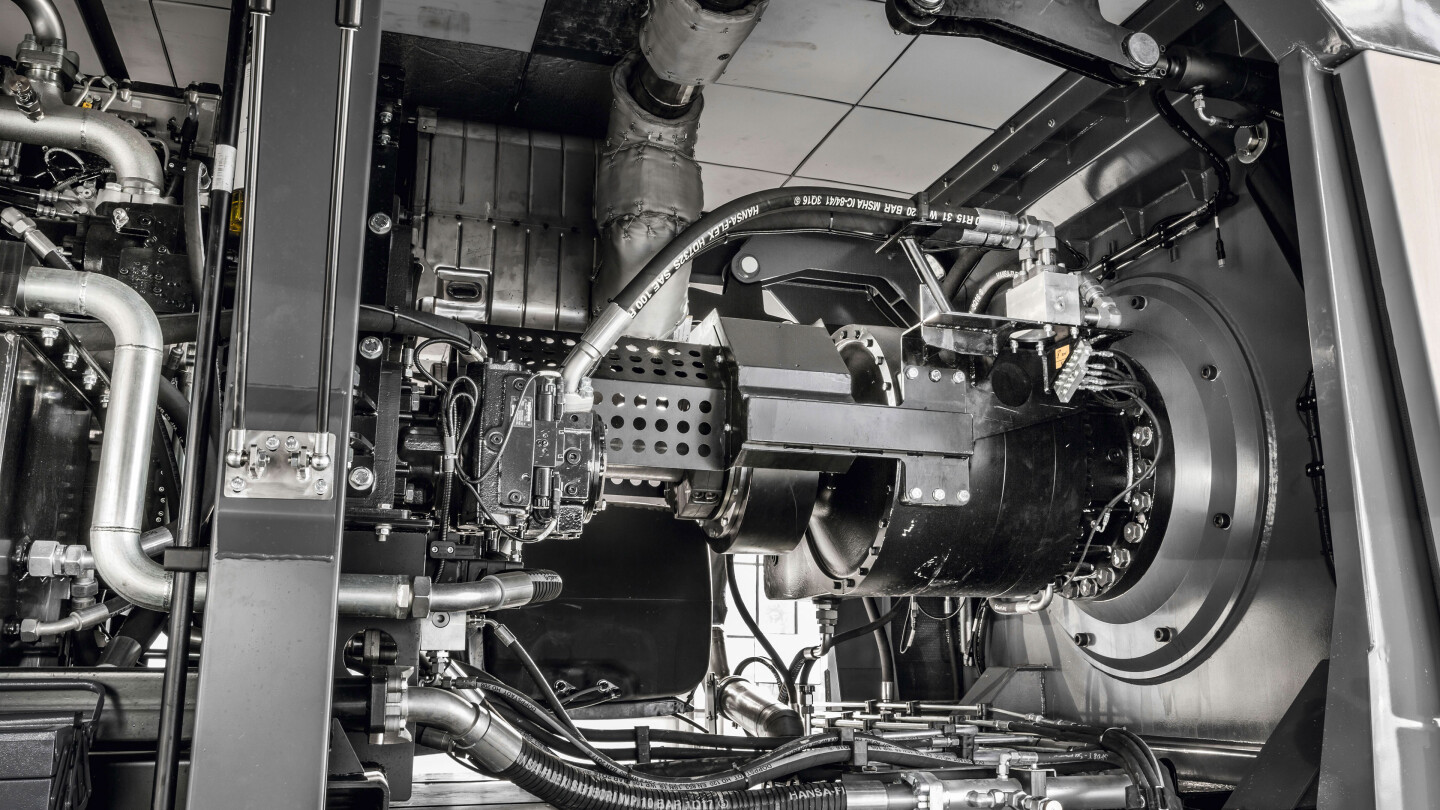

The INVENTHOR TYPE 9 opens up completely new possibilities when it comes to effective shredding: From material feed to product removal, it stands out thanks to a whole number of innovations – for instance, the new VarioDirect Drive, which continuously transmits power to the shredding drum so that the engine always runs at the optimum operating point, or the new enclosure concept ensuring optimal accessibility from all sides.

NEW DEVELOPMENTS THAT MAKE A DIFFERENCE

Discover the wide variety of application of the largest mobile slow-speed grinder:

Waste wood processing

Commercial waste recycling (click here)

Refuse derived fuel processing (click here)

The Inventor Type 9 shredder is a high-performance solution for processing a range of waste materials, including biomass, scrap wood and mixed construction waste and so on.

INVENTHOR TYPE 9: A CLOSER LOOK

NEW COOLER DESIGN

Very efficient cooler geometry, right in front of the hydraulically, reversible cooler

NEW CASING CONCEPT

For optimum accessibility, all doors open upwards. The GRP doors including vent slots efficiently reduce noise emission.

NEW – COMB FLAP

The comb flap opens up to 120°, providing easy access to the entire grinding compartment.

It also further improves operational safety and ensures immediate machine availability following maintenance and service work.

NEW – MATERIAL FEED AND

GRINDING COMPARTMENT

NEW DRIVE CONCEPT

The new patented Vario Direct Drive allows for continuous, variable power transmission directly to the grinding drum.

Efficient, flexible, performance-oriented

- Starting up the machine when loaded– the new drive concept delivers the necessary torque to start shredding from standstill;

- The integrated cleaning system enables the automatic cleaning of any long materials that become wrapped around the shredding drum;

- Flexible shredding concept with different shredder packages (sizes S to XL, consisting of drum/teeth + toothed bar + limiter) allows for a precise adaptation to the respective material requirements;

- Plug and play: After lowing the conveyor belts to the working position, the machine is immediately ready for use at the press of a button;

- Excellent monitoring concept for the entire shredding process;

- Reduced noise emissions;

- It is now possible to select a wheeled semi-trailer (SA) or track-mounted undercarriage (K) as chassis versions as well as different rear belt lengths (7 m, 8.5 m or fixed as 12 m) for maximum conical pile.

THE GRINDING CONCEPT. Proven and still improving.

The INVENTHOR Type 9 is used for on-site volume reduction, primary size reduction following homogenization in bio-mechanical treatment and recycling plants, for waste wood treatment and the homogenization process in thermal waste treatment.

Setting new standards for the recycling process:

- High flexibility thanks to a variety of grinding systems to choose from

- Outstanding power reserves for the most demanding requirements

- Immediate machine availability after service

- Work and improved operational safety

- High-quality, future-proof technology

- Reduced noise emission

- Sophisticated monitoring of the entire grinding process

- Maximum throughput rate

Looking for more information?